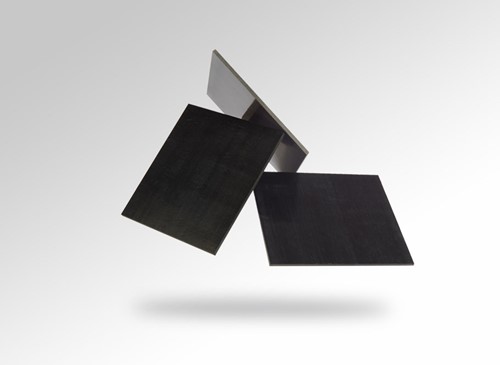

CUSTOM PAEK LAMINATE PANELS & PREFORMED INSERTS

Delivered to meet the technical and business needs of commercial aerospace

MANUFACTURED FOR EXCELLENCE

We bring together detailed process controls and manufacturing capabilities from automated composite layup thorough inspection to produce tailored PAEK laminates and inserts to meet your requirements.

Advanced manufacturing

We combine advanced process control techniques and state-of-the-art automation to achieve unrivaled production speeds – without sacrificing quality.

High-volume production

Our rapid manufacturing techniques allow for cost-effective part solutions from single toolsets – able to cope with even the highest volumes.

Repeatable part production

We ensure the highest quality parts by maintaining traceability – from raw material inputs to finished goods – controlling our processes throughout.

Designing a Tailored Composite Laminate

Composites materials can derive up to 60% of their mechanical properties from fibers by volume but unlike metal, fibers do not contribute uniformly to the strength of the composite in all directions. For metals, it doesn’t matter which direction you push or pull from, they will react in the same way. We refer to this uniformity across all axes, as isotropy. In composites, the behavior of a laminate is dominated by the fibers. This different behavior in different directions makes fiber-reinforced composites anisotropic.

One of the first considerations in designing a tailored composite laminate is to understand the application demands, more specifically the direction of the applied loads in all load cases. If the application only needs to handle a tensile load in a single direction, you would align the fibers in that direction and in a quantity needed to meet the load requirements.

The next consideration is the stability of the composite structure. Rather than align the fibers or tape 100% in one direction, it’s important to offset it with fibers that run across the load direction. These crossing fibers allow the aligned fibers to work more efficiently by helping to distribute load across the ply width and through the thickness of the laminate. These connections add strength to the overall laminate. From there you can build up the layers to meet the stress requirements of the application.

Looking for PEAK laminate panels or inserts with tailored mechanical properties?

TxV delivers high-quality PAEK laminate panels and inserts with full traceability to raw materials

Explore more produtcs

Our Capabilities

AEROSPACE QUALITY COMPOSITE PARTS & ASSEMBLIES

AS9100 Certified Quality Management System

TxV Quality Policy

TxV Aerospace Composites realizes Customer Satisfaction by:

- Providing best value

- Meeting or exceeding all customer requirements

- Realizing quality objectives

- Pursuing continual improvement